-

- Alle Zentrifugen

- Tischzentrifugen

- Standzentrifugen

- Gekühlte Zentrifugen

- Mikrozentrifugen

- Mehrzweckzentrifugen

- Hochgeschwindigkeitszentrifugen

- Ultrazentrifugen

- Concentrator

- IVD Produkte

- High-Speed and Ultracentrifuge Consumables

- Zentrifugenröhrchen

- Zentrifugenplatten

- Gerätemanagement

- Proben- und Informationsmanagement

-

- Alle Pipetten, Dispenser und automatischen Liquid-Handling-Systeme

- Mechanische Pipetten

- Elektronische Pipetten

- Mehrkanalpipetten

- Direktverdrängerpipetten & Dispenser

- Pipettenspitzen

- Flaschenaufsatzdispenser

- Pipettierhilfen

- Zubehör für Dispenser & Pipetten

- Automatisches Pipettieren

- Verbrauchsartikel für die Automation

- Zubehör für die Automation

- Services für Dispenser & Pipetten

Basics in Centrifugation - Calculating relative centrifugal force and selecting a centrifuge and rotors

Lab Academy

- Cell Biology

- Centrifugation

- Centrifuges & Rotors

- Essay

What is a centrifuge, and how does a centrifuge work?

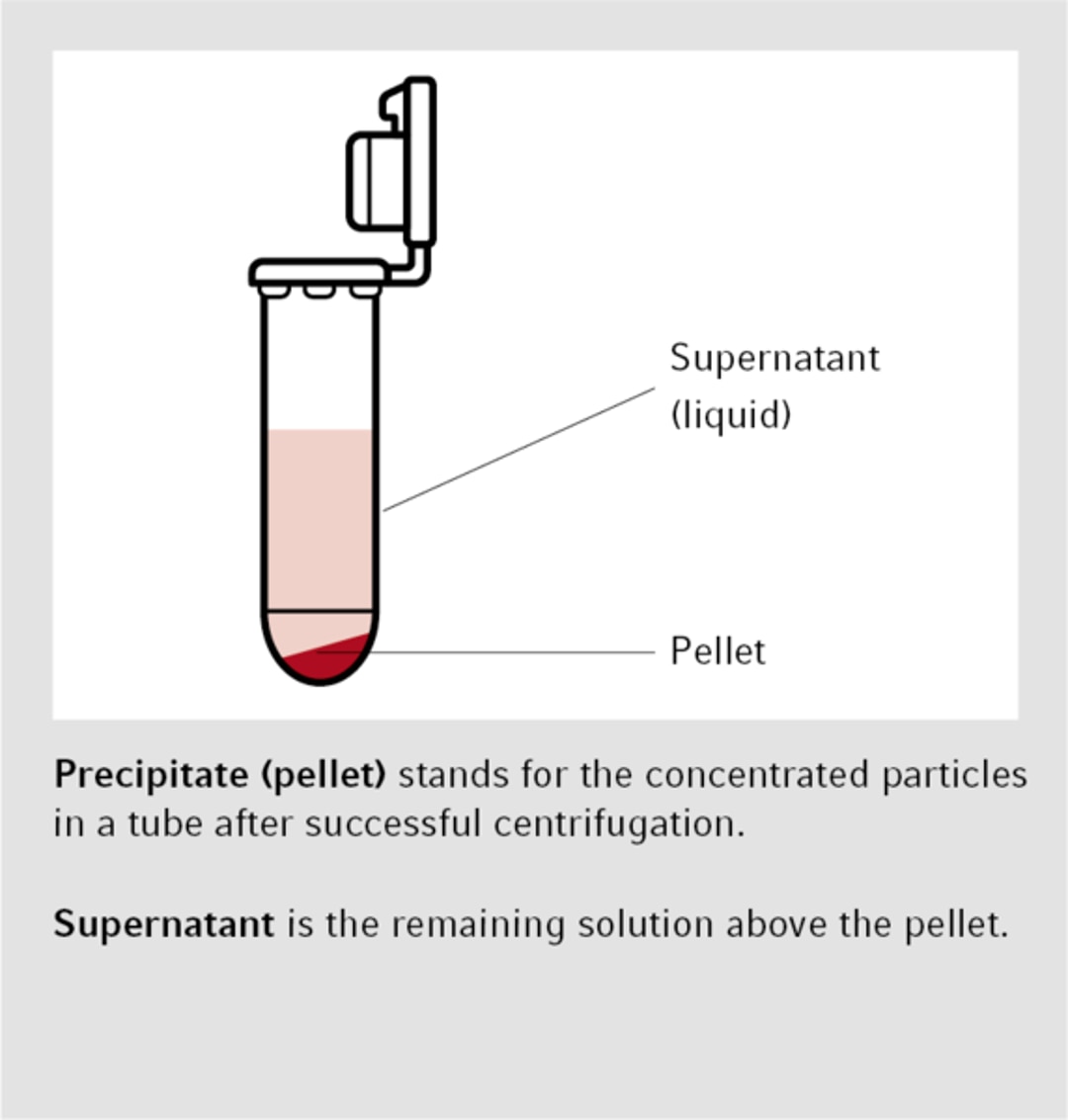

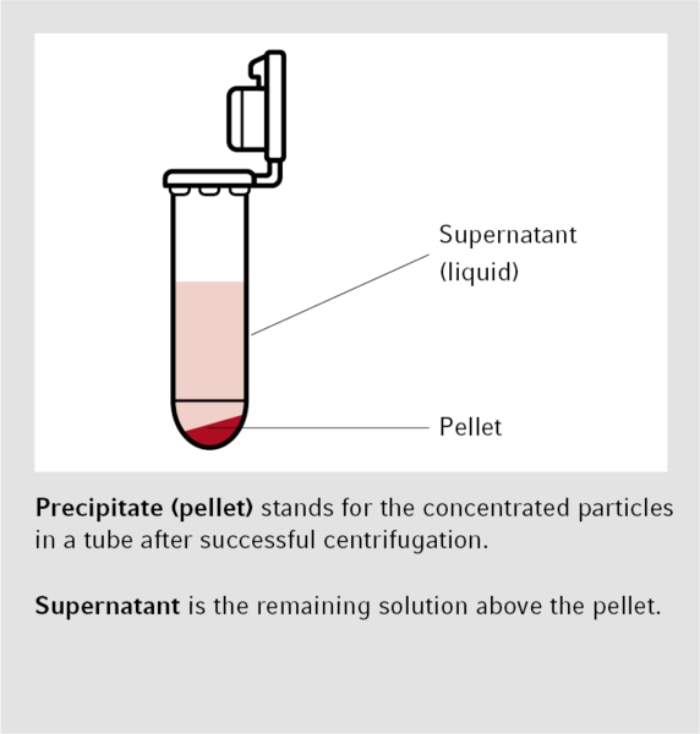

Pelleting is the most common application for centrifuges in laboratories. Here, centrifugal force concentrates into a pellet at the bottom of the centrifuge tube, with the pellet being separated from the remaining solution (supernatant). During phase separation, chemicals are converted from a matrix or an aqueous medium to a solvent (for additional chemical or molecular biological analysis).

In ultrafiltration, macromolecules are purified, separated, and concentrated by using a membrane. Isopycnic centrifugation is carried out using a "self-generating" density gradient established through equilibrium sedimentation. This method concentrates the analysis matches with those of the surrounding solution. Protocols for centrifugation typically specify the relative centrifugal force (rcf) and the degree of acceleration in multiples of g (g-force). Working with the rotational speed, such as revolutions per minute (rpm), is rather imprecise.

Mehr erfahren

Important definitions

Degree of acceleration

In general, applications for centrifugation specify the degree of acceleration to be applied to the sample rather than specifying a specific rotational speed such as revolutions per minute. The acceleration is typically given in gravity [× g] (or multiples of x g or g-force), the standard acceleration value due to gravity at the Earth’s surface (9.81 m/s2).

Mehr erfahren

Rcm vs rpm:

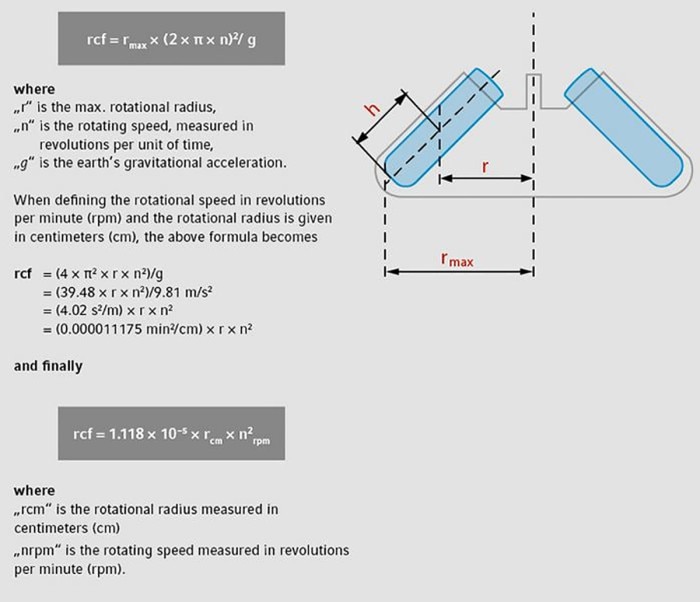

The distinction between rcf and rpm is important, as two rotors with different diameters running at the same rotational speed (rpm) will result in different accelerations (rcf).

Mehr erfahren

How to calculate relative centrifugal force (rcf)

As the motion of the rotor is circular, the acceleration force is calculated as the product of the radius and the square of the angular velocity. Historically known as “relative centrifugal force” (rcf), this is the measurement of the acceleration applied to a sample within a circular movement. This process is measured in units of gravity (× g).

Mehr erfahren

Example g to rpm conversion*

| Rotor A | Rotor B | |

| Speed | 14,000 rpm | 14,000 rpm |

| Radius | 5.98 cm | 9.50 cm |

| Gravity | 13,100 x g | 20,817 x g |

Mehr erfahren

Mehr erfahren

If your centrifuge does not have a rcf-rpm converter, you may use the formula above or the rcf-rpm calculator tool below. Alternatively, rcf-rpm calculators and g to rpm calculators can be found on centrifuge supplier websites, or a nomogram for conversion.

Mehr erfahren

Centrifuge g to rpm Speed Calculator

Mehr erfahren

A small k-factor represents a more rapid separation. The value of the k-factor is primarily determined by the rotor diameter. Compared to rpm/rcf, the usage of the k-factor has become less important for general centrifugation processes. Especially for ultracentrifugation, the k-factor is still relevant.

How to select the right centrifuge for your application

If you follow a given protocol, make sure to use the same type of rotor and apply the given relative centrifugal force (rcf) as well as the same temperature and running time. In general, the following major parameters have to be determined for a successful centrifugation run:

A: Type of sample

B: Vessel selection

C: Type of centrifuge

D: Type of rotor

E: Determination of desired relative centrifugal force

F: Defined temperature during centrifugation

Mehr erfahren

Fixed-angle or swing-bucket rotors?

The most common rotors in laboratory centrifugation are either fixed-angle or swing-bucket rotors. Only a few applications require special rotors such as continuous-flow rotors, drum rotors, and the like. Flow-through rotors enable continuous flow collection of precipitates. These systems are used, e.g., in harvesting fermenters or for juice production in the food industry. Special customized versions, optimized for the specific application, are necessary.

Mehr erfahren

Fixed-angle rotor

The obvious advantage is the lack of moving parts in the rotor. This results in lower metal stress (longer lifetime), a higher maximum g-force is possible and for many applications, faster centrifugation times can be realized.

Mehr erfahren

Swing-bucket rotor

This kind of rotor is highly flexible for using different tube formats, including SBS-format plates, based on a broad range of adapter systems and a high sample capacity.

Mehr erfahren

The centrifuge

In general, centrifuges are classified either as floor-standing or bench-top models.

Mehr erfahren

Videos not loading, because cookies have been rejected. Change your

Floor-standing centrifuges

Mehr erfahren

Mehr erfahren

Bench-top centrifuges

Mehr erfahren

- Microcentrifuges

Microcentrifuges are optimized for low-volume tubes, have a small footprint, and provide 14,000 to 30,000 × g for up to 48 microtubes. Some devices can even be used for a few 15 mL or 50 mL conical tubes or 2 SBS-format plates. Many suppliers offer non-refrigerated and refrigerated versions and different sizes of devices based on their tube capacity.

Explore Eppendorf microcentrifuges

- Multipurpose centrifuges

Offering a bigger rotor chamber, multipurpose centrifuges allow a broad range of rotors to be used (highly versatile). In addition to a flexible rotor system, specific adapter systems enable use of a wide variety of different kinds of tubes and bottles (from 0.2 mL to 1,000 mL) as well as plates. The maximum speed heavily depends on the vessel’s characteristics.

Explore Eppendorf multipurpose centrifuges

Mehr erfahren

Centrifuge Maintenance and Safety

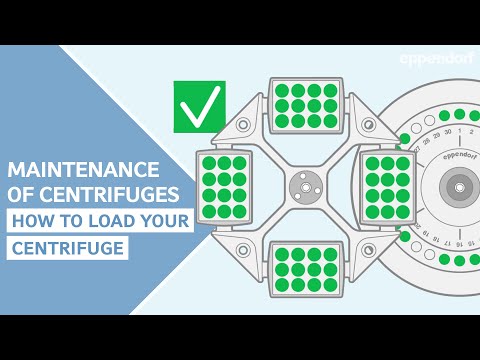

No matter which type of centrifuge you choose, routine centrifuge maintenance is a must to ensure safe and effective centrifugation. This includes regularly inspecting the centrifuge and rotors for signs of corrosion or damage, in addition to cleaning, disinfection, sterilization (especially if dealing with pathogenic samples), and lubrication. Following best practices for safe operation is also essential, including correctly balancing samples and loading the rotor.

Mehr erfahren

Videos not loading, because cookies have been rejected. Change your

Mehr erfahren

Centrifuge Speed Calculator

Mehr erfahren